One of the most straightforward pieces of machinery in the manufacturing industry, the diaphragm pump is responsible for a significant but often unnoticed role in the production process. Located in the very heart of the entire industrial sector, it was chosen for its location.

Through its mastery of fluid expertise and rhythmic breathing, this gentle giant can power a vast number of processes in a completely silent manner.

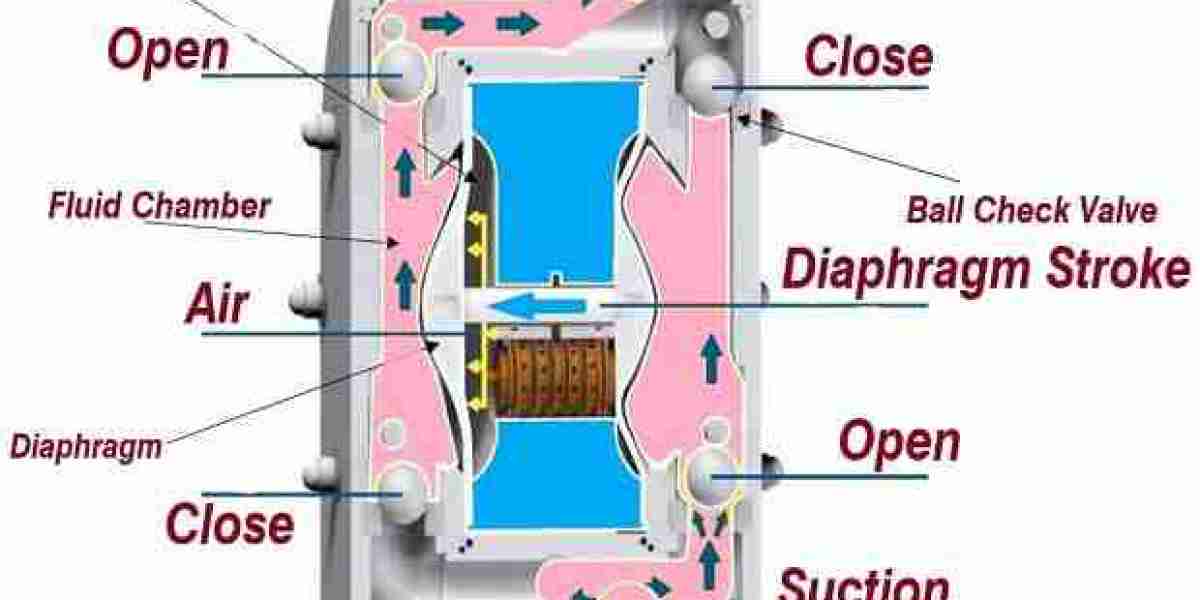

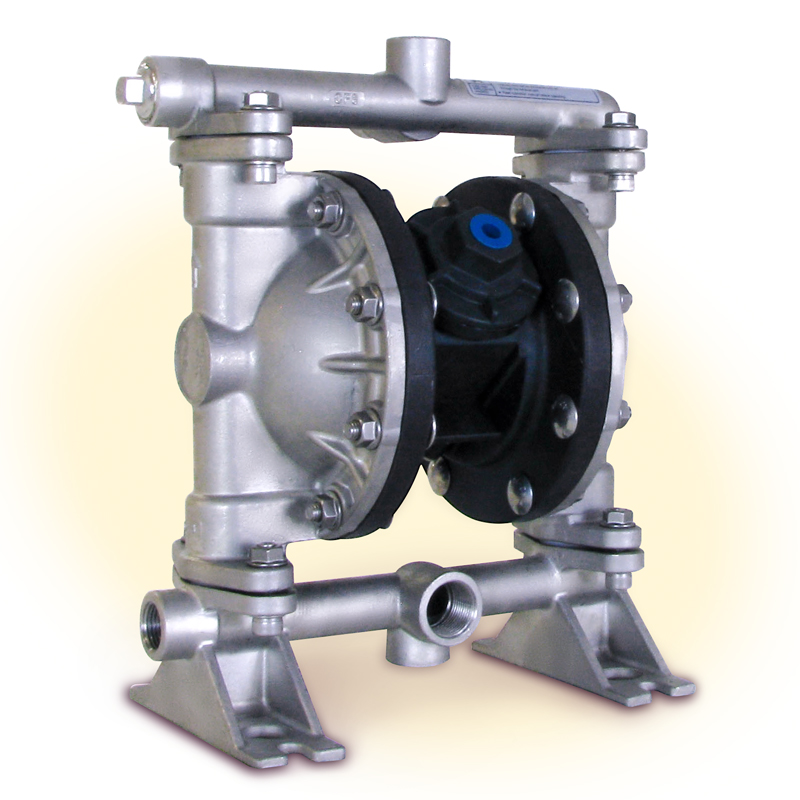

The middle of each air diaphragm pump how it works contains two diaphragms that are flexible and are located in the middle of the pump. One could say that these diaphragms perform a function that is analogous to that of a pair of lungs that are both robust and flexible. As

Inhaling compressed air causes one of the diaphragms to expand outward, which in turn leads to the formation of suction, which in turn causes fluid to be inhaled. This process continues until the fluid is exhaled.

by making use of intake valves that are in an open position. The other, on the other hand, is taking a breath, and its diaphragm is contracting to force fluid forward. During the time that the other is taking a breath, this is taking place.

to what location within the system the discharge valves are located.

Both sets of lungs take turns doing the work of breathing in and out, and they do so in perfect harmony with one another. This occurs during the process of breathing in and out. Each of their chests moves up and down in time with the movements that they are making.

gracefulness, avoiding any harsh surges that could potentially damage delicate cargoes, and avoiding any potential impacts are all things that should be avoided. The flow of the fluids is consistent and unbroken throughout the entire experience.

There is an additional benefit associated with air diaphragm pump how it works, which is that none of their internal shafts need to be submerged in fluid to function properly. An important benefit is that this is the case. These people are protected from getting affected by this.

There are a variety of things that have the potential to sustain damage. Some examples include seals that are prone to breaking and components of rotating motors that are typically worn out. Additionally, because they have external lungs with them, they can self-regulate their breathing conditions.

Diaphragm pumping has quietly positioned itself at the centre of a significant number of different industries by providing a service that is not only dependable but also sensitive. This recognition has been achieved through the provision of a service.

In circumstances in which liquids must be transported in a gentle manner, such as when chemical dosing, the transfer of food, or mining slurries are involved, these gentle techniques are utilized.

Through the utilization of ingenious mechanisms that are located within their bodies, giants can bring life into existence. The machines that are the most powerful are typically the ones that can accomplish the most goals while they are functioning.

results in the audience paying the least amount of attention to the performance.

According to the requirements of their operations, the following is a list of the most significant industrial sectors that frequently make use of diaphragm pumps:

Because of their high compatibility with abrasive fluids and their relatively consistent performance, air diaphragm pumps and how they work are utilized in a wide variety of applications.

transport a diverse assortment of wastewater, which may include sewage and wastewater from industrial establishments, amongst other types of wastewater. In addition to this, they can also be utilized in the manufacturing of clean drinking water.

the process of creating chemical substances

The designs of diaphragm pumps, which do not include rotors or seals, allow them to completely isolate fluids from the environment that they are surrounded by. This is because diaphragm pumps do not contain any of these components.

The chemical industry, the beverage industry, and the pharmaceutical industry all make significant use of them. There is also a significant amount of utilization in the pharmaceutical industry.

The industry that deals with natural gas and petroleum

Application examples include the transportation of drilling mud and crude oil, as well as the delivery of fuel to gas stations. Other examples include the transportation of fuel to gas stations. There are also other examples, such as the transportation of both.

The production of agricultural goods and the beverage industry jointly

One of the most common applications is the transfer of liquids such as alcohol, juices, and sauces, which require a transfer that is free of any contaminants. Within the context of the transportation of these liquids, this kind of transfer is necessary.

In the mining industry, two examples include the transportation of slurry and the recovery of filtrate. Both of these processes are examples of mining.

As a result of the exceptional performance characteristics that they possess, diaphragm pumps are primarily utilized in a variety of applications.

In the industrial sector, many different sectors operate in environments that are demanding and have significant requirements for liquid transfer. They have ownership of it.

Self-priming and seal-less configurations offer some distinct advantages in comparison to other types of pumps, and these advantages can be applied to a wide variety of process applications. These advantages can be found in the fact that they can eliminate the need for a seal.