The latest report by IMARC Group, titled “Tooling Board Market Report by Material (Polyurethane, Epoxy Resins, and Others), Application (Aerospace and Defense, Automotive, Marine, Wind Energy, and Others), and Region 2024-2032”, offers a comprehensive analysis of the industry, which comprises insights on the market.

Tooling Board Market Forcast:

The global tooling board market size is expected to exhibit a growth rate (CAGR) of 3.69% during 2024-2032.

Competitive Landscape:

The competitive landscape of the market has been studied in the report with detailed profiles of the key players operating in the market.

- Alchemie Ltd.

- Alro Steel Corporation

- Base Materials Ltd

- Coastal Enterprises

- Curbell Plastics Inc.

- General Plastic Manufacturing Co.

- Goldenwest Manufacturing Inc.

- Huntsman Corporation

- OBO-Werke GmbH

- RAMPF Holding GmbH & Co.KG

- Sika AG

- Trelleborg AG

Factors Affecting the Growth of Tooling Board Industry:

- Versatility and Customizability:

Tooling boards offer remarkable versatility and customizability, making them highly desirable in various industries. These boards are available in a range of densities, hardness levels, and machinability options, allowing manufacturers to select the most suitable material for their specific application requirements. Whether it is for creating intricate prototypes in automotive design or producing precise molds for aerospace components, tooling boards offer the flexibility needed to meet diverse manufacturing needs. Furthermore, tooling boards can be easily machined, shaped, and finished to achieve the desired specifications with precision. Manufacturers can use standard machining techniques such as milling, routing, and drilling to create complex geometries and fine details, enabling efficient and cost-effective prototyping and tooling processes. This versatility streamlines production workflows and reduces lead times, making tooling boards a preferred choice for rapid prototyping and iterative design processes.

- Durability and Stability:

Another driving factor behind the widespread adoption of tooling boards is their exceptional durability and stability. These boards are engineered to withstand the rigors of manufacturing processes, including molding, casting, and machining, without compromising on performance or dimensional accuracy. Unlike traditional materials such as wood or plaster, tooling boards exhibit superior dimensional stability, resisting warping, shrinking, or expanding due to changes in temperature, humidity, or mechanical stress. This inherent stability ensures consistent results and minimizes material waste, contributing to cost savings and operational efficiency. Whether it is for producing one-off prototypes or high-volume production runs, manufacturers can rely on the durability and stability of tooling boards to deliver reliable and repeatable results. Moreover, the resistance to chemical, solvent, and moisture damage further extends the lifespan of tooling boards, making them suitable for long-term use in demanding industrial environments.

- Increasing Cost-Effectiveness and Sustainability:

Cost-effectiveness and sustainability are significant factors driving the adoption of tooling boards in modern manufacturing operations. Unlike traditional tooling materials such as metals or composites, tooling boards offer a more affordable alternative without compromising on performance or quality. The lower material costs coupled with reduced machining times and minimal post-processing requirements make tooling boards a cost-effective solution for prototyping, tooling, and production applications. Moreover, the lightweight nature of tooling boards compared to metals translates to lower shipping and handling costs, further contributing to overall cost savings. Additionally, the machinability of tooling boards allows for efficient material utilization, minimizing waste and optimizing resource allocation. This reduces material costs and also aligns with sustainability initiatives aimed at minimizing environmental impact and promoting responsible manufacturing practices.

For an in-depth analysis, you can request a sample copy of the report: https://www.imarcgroup.com/tooling-board-market/requestsample

Tooling Board Market Report Segmentation:

By Material:

- Polyurethane

- Epoxy Resins

- Others

Polyurethane dominates the market due to its versatility, durability, and cost-effectiveness across a wide range of industrial applications.

By Application:

- Aerospace and Defense

- Automotive

- Marine

- Wind Energy

- Others

Aerospace and defense hold the maximum number of shares due to the stringent quality standards, complex engineering requirements, and high demand for advanced materials and technologies within the industry.

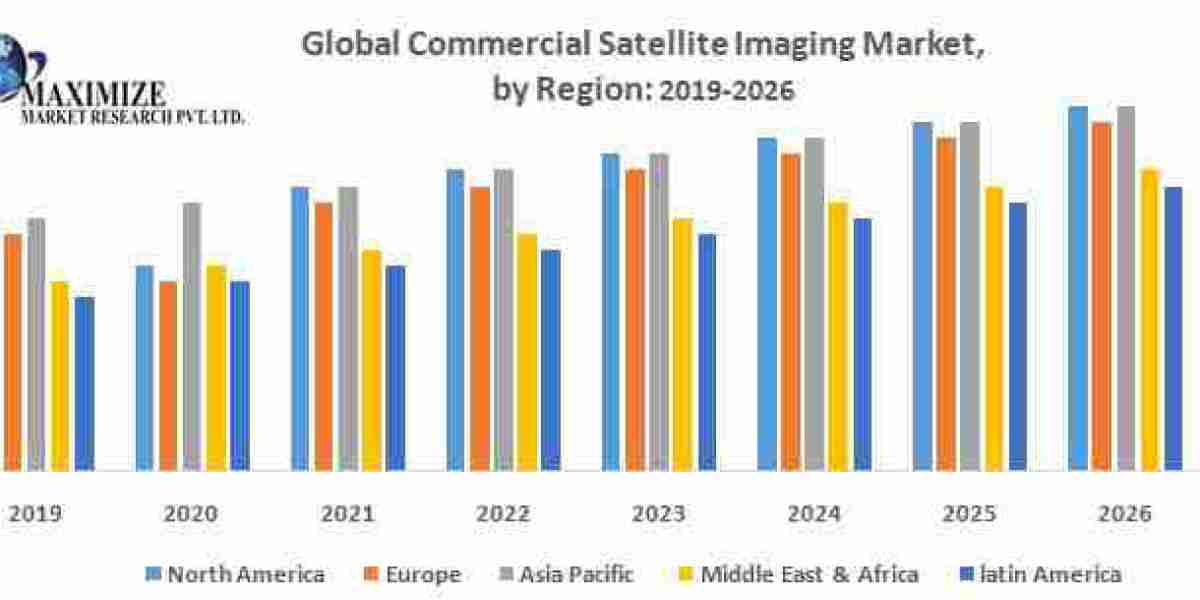

Regional Insights:

- North America (United States, Canada)

- Asia Pacific (China, Japan, India, South Korea, Australia, Indonesia, Others)

- Europe (Germany, France, United Kingdom, Italy, Spain, Russia, Others)

- Latin America (Brazil, Mexico, Others)

- Middle East and Africa

Europe’s dominance in the tooling bord market is attributed to its robust industrial base, strong emphasis on innovation, and favorable regulatory environment fostering market growth.

Global Tooling Board Market Trends:

Tooling boards are prized for their ease of handling and machining, which significantly contribute to their popularity in various industries. Unlike traditional materials that may require specialized handling or processing techniques, tooling boards are lightweight and can be easily transported, stored, and manipulated by manufacturers. This ease of handling streamlines production workflows, reduces labor costs, and enhances operational efficiency. Moreover, tooling boards are machinable with standard equipment and tools commonly found in manufacturing facilities, eliminating the need for expensive or specialized machining setups. This accessibility allows manufacturers to leverage existing infrastructure and expertise, lowering barriers to entry and facilitating broader adoption of tooling boards across different sectors. Whether it is for small-scale prototyping or large-scale production, the ease of machining ensures quick turnaround times and enables agile manufacturing processes.

Ask Analyst for Customization: https://www.imarcgroup.com/request?type=report&id=3419&flag=C

Note: If you need specific information that is not currently within the scope of the report, we will provide it to you as a part of the customization.

About Us

IMARC Group is a leading market research company that offers management strategy and market research worldwide. We partner with clients in all sectors and regions to identify their highest-value opportunities, address their most critical challenges, and transform their businesses.

IMARCs information products include major market, scientific, economic and technological developments for business leaders in pharmaceutical, industrial, and high technology organizations. Market forecasts and industry analysis for biotechnology, advanced materials, pharmaceuticals, food and beverage, travel and tourism, nanotechnology and novel processing methods are at the top of the company's expertise.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

IMARC Group

134 N 4th St. Brooklyn, NY 11249, USA

Email: sales@imarcgroup.com

Tel No:(D) +91 120 433 0800

United States: +1-631-791-1145 | United Kingdom: +44-753-713-2163